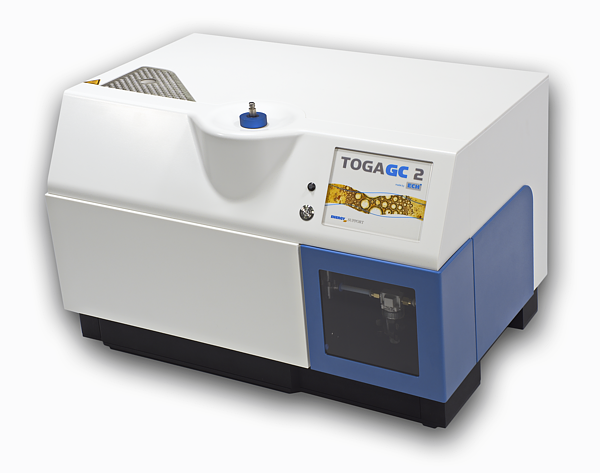

TOGAGC 2

Gas Analytics

Downloads

Downloads

TOGAGC 2

TOGAGC 2

Dissolved gas analysis with automated full vacuum degassing

Conform to the standards ASTM D 3612, IEC 60567

Distribution by Energy Support GmbH - www.energy-support.de

Product description

The animation shows the operation of the TOGA GC 2.

- Complete gas-in-oil analysis (11 gases) and Total Gas Content

- Auto sampler for 16 and 32 samples available

- Expert system for quick and easy evaluation

The TOGA GC 2 has been designed for a fast and reliable measurement routine. The analysis - done in 2 steps - follows the standard guidelines of ASTM D 3612 and IEC 60567.

For many decades Dissolved Gas Analysis has proven to be a favourable method for insulation diagnostics. The TOGA GC 2 has been developed to be user-friendly and delivers reliable and accurate results. The analysis system allows a calibration of the complete system following the measurement routine.

Total Gas Content

Equally important for insulation diagnostics is the Total Gas Content (TGC).

The TOGA GC 2 is currently the only system which measures the TGC during the degassing process accurately. The increase in the TGC is a clear indication of existing faults in the transformer, which can be thermal, electrical or mechanical in nature.

The analysis is done in 2 steps with high selectivity and accuracy, fully compliable with laboratory procedure. Degassing of the oil sample is done through multi-periodic vacuum extraction (according to ASTM D 3612 and IEC 60567). The gas sample is automatically transferred to the GC.

Gas chromatographic analysis is done with a Thermal Conductivity Detector (TCD), Flame Ionisation Detector (FID) and with a Methanizer. All results are displayed in ppm, sensitivity is as low as 0.1 ppm for hydrocarbons. Therefore, new transformer oils and transformers following their periodic maintenance can also be analysed. Besides the results, all other operating conditions are registered and stored in a file together with all remaining parameters. The graphics of the results is displayed in real time on the monitor, in the table or/and as a test report in a print file. The integrated Expert System will evaluate the results according to international standards like „Duval“ or „IEC“.

Key benefits of the TOGA GC 2

- Compact design: 530 x 355 x 370 mm

- Highly efficient vacuum extraction + GC (no head space)

- Fantastic repeatability and accuracy

- Power consumption less than 1 kW

- 50 mL sample injection by glass syringe (no additional prep)

- Multi-detector system with FID and TCD

- Complying with ASTM D 3612 and IEC 60567

- Works with any oil type (mineral oil or natural esters)

- Doesn't need solubility coefficients

- Individual column ovens for independent and optimised temp. programs at the same time

- TCD robust against carrier gas interruption

- Fast oven cooling: within 3 minutes from 250 to 50 °C

- Independent calculation of total gas content even before chromatogram by pressure difference after sample injection

- Integrated expert system tool for result interpretation

- Simple and cheap calibration by standard gas mixture

- Customisable protocol generator

- 100 % developed and manufactured in Germany

- Recommended method by Transformer Magazine for factory test of new transformers

Advantages

- One-touch operation

- Accurate measurement of total gas content

- Most sensitive detection for Acceptance-, Service- and Routine tests (0.1 ppm)

- Adaptable for Factory Transformer Heat-Run tests

- Ideal solution for laboratories and workshops

Applications

- Insulating oil

- Mineral oil

- Lubrication fluids

- Engine oil

- Gear oil

- Hydraulic fluids

- Biodiesel

Features

- Fully automatic procedure

- Multi-periodic vacuum degassing

- Full Dissolved Gas Analyses (11 gases) and Total Gas Content

- Automatic transfer of gas sample

- Easy calibration of the whole system with traceable calibration gas

- Auto sampler available for 16 or 32 samples for unattended operation

- Expert System for quick and easy result evaluation

- Evaluation according to: IEC 60599, Roger ratios, Duval etc.