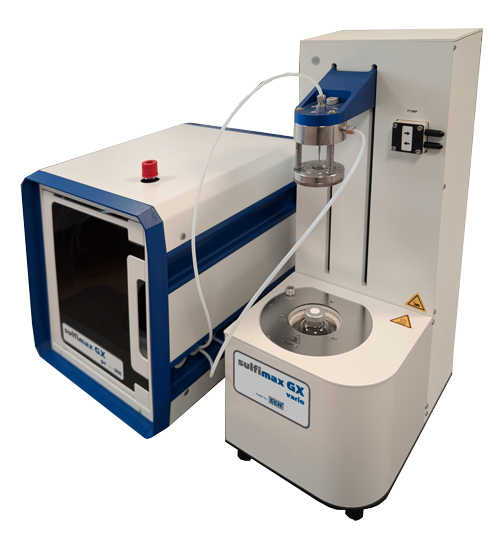

Sulfimax GX Vario

Automated H2S determination

Determination of H2S in liquids, oils, viscous and solid samples

Conform to standards of ASTM, DIN

The determination of volatile hydrogen sulphide (H2S) in liquid, solid and gaseous samples is now very easy. By effective gas extraction, the H2S is completely expelled from the sample. The released H2S gas is transfered to the highly sensitive sensor, which detects H2S in the range of 0.01 to 10,000 ppm. A typical measurement takes 5 - 30 min depending on the sample composition.

The H2S analyzer Sulfimax GX of the ECH is extendable with a new heating oven module for headspace-based sample preparation. The sample is filled in a glass vial and heated in the headspace module. Depending on its composition, it can be heated at temperatures ranging from 35 to 250 °C.

Interference from mercaptans – as expected in oil samples – can be avoided by using the oil washing vessel.

High concentrations of mercaptanes are tolerated.

The compact and robust device can be easily operated by everyone. The Sulfimax GX Vario PLUS enables automated determination of H2S without manual handling of digestion reagents for the first time.

Applications

ECH's Sulfimax analytical systems for H2S determination, coupled with the Vario Headspace Module, allow the analysis of the following sample types:

- Solid samples, e. g. elementary sulphur, sludge, bitumen

- Liquid samples, e. g. wastewater with and without sludge particles, sewage sludge

- Crude oil, petrochemical products

- Process waters

- Gas samples, e. g. process gases, LPG

- Soil samples and waste

Advantages

- Easy extension of the H2S analyzers Sulfimax GX for automation

- No sample preparation necessary for high viscous samples

- Very low H2S concentrations detectable

- Suppression of cross-sensitivity of mercaptans

- Completely closed extraction vessels

- Low cost chemicals and vials

- Low waste (no organic cleaning solvents or cartridges)

Features

- Measurement of the sample in the sealed 20 mL disposable vial - no contact of the sample with components of the analysis system

- Gas extraction technique for rapid release and separation of H2S from the sample

- Temperature control from 35 to 250 °C

- Measuring time from 5 to approx. 30 min, depending on the H2S and mercaptan content of the sample

- Double-needle system for gas transfer

- Bypass circuit for continuous gas flow

- Automatic conditioning after each measurement

Standard conformity

The measuring principle for determine the sulphide/H2S in aqueous samples fully complies with the standard DIN 38405-27: 2017 and the new ASTM D 8536-25.

The measurement principle for oil and fuels is similar to the method described in standards IP 570 and ASTM D 7621. It combines gas extraction with a selective washing process to suppress mercaptan interference at the sensor (without filter cartridges).

Sulfimax GX Serie Overview

Sulfimax GX Serie Overview